What an IT Manager says about the Wattsense solution

After the publication of our last case study, in which the apple producer MESFRUITS optimized the energy consumption of its cold rooms thanks to Eqinov and Wattsense. We spoke to Guillaume Simon, IT Manager at Eqinov, so that he could share with us his experience of the Wattsense solution from a technical point of view.

Why did Eqinov choose the Wattsense solution to achieve its goals instead of other market options?

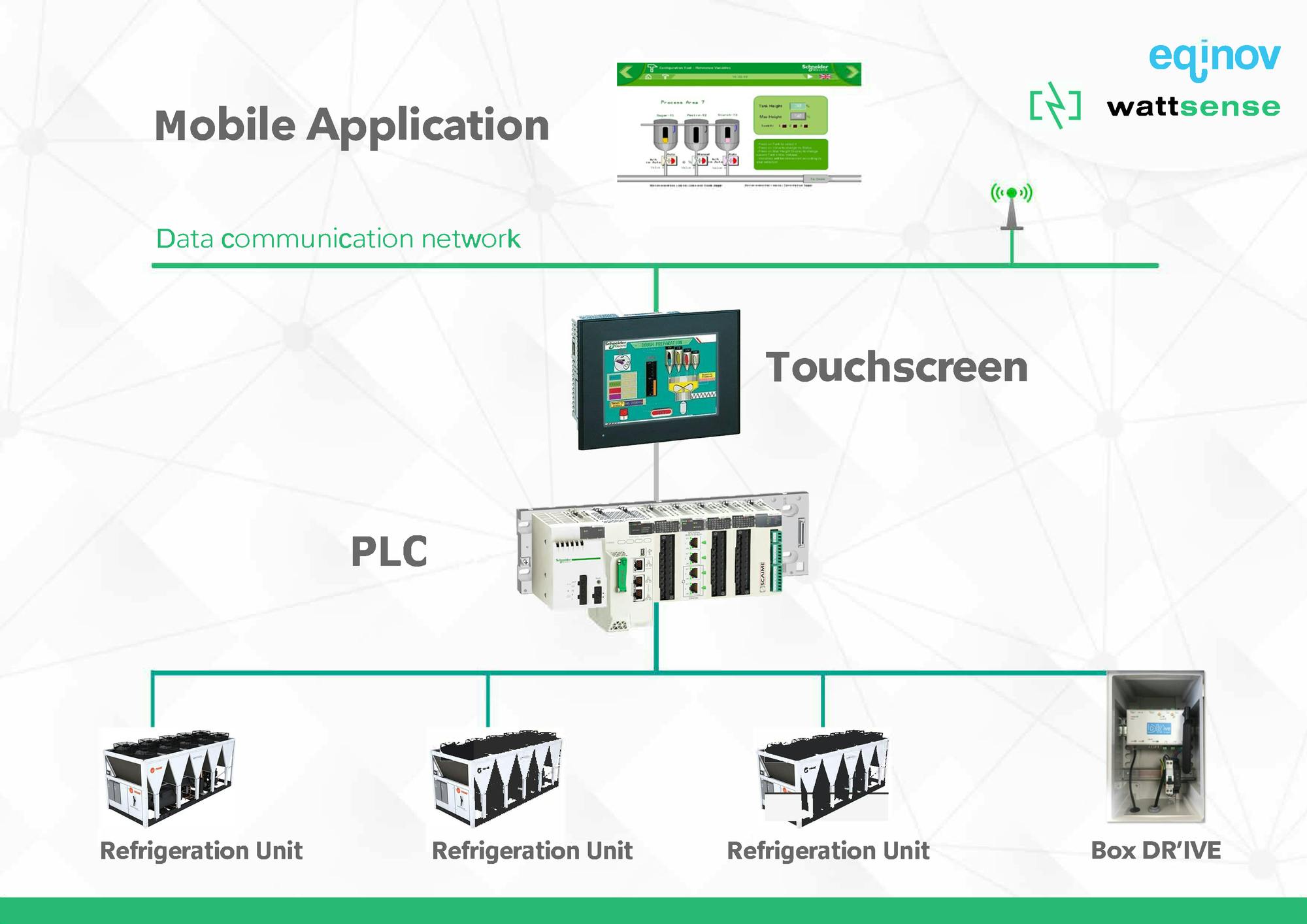

Previously, Eqinov already used systems to control equipment remotely with Programmable Logic Controllers (PLC) and the Siemens Telecontrol app. But this solution is costly, around 3,000€ for controlling a site. Besides, it forces us to use an integrator with skills in Siemens automation, skills that we don't have internally.

We decided to carry out a market study in order to determine which system would allow us to be more independent when managing and collecting data on-site. Our main goal was to make Eqinov as autonomous as possible, without having to depend on an integrator. We also had certain technical constraints. In the event of a request for load management, the commands must reach the equipment or the supervision system of Eqinov customers without delay. We also needed a system that allowed us to collect energy data (electricity or gas consumption, temperature, etc.) in configurable time steps.

Can you describe the process for choosing the Wattsense solution for the MESFRUITS project?

We decided to test the Wattsense solution in our premises at first as part of a POC (Proof of Concept): a Raspberry Pi card controlled a fan and lighting via a relay and collected the temperature of a sensor. The system communicated in Modbus with the Wattsense Box.

This POC enabled us to draw the following conclusions:

• The Wattsense solution is quick to send commands.

• The data collection process is configurable.

• Equipment management and data reporting can be done via a Rest API between our Dreams © application and the Wattsense solution.

We also appreciate:

- The variety of communication protocols supported by the solution, which makes it possible to adapt to any technical system encountered in the field.

- To be able to directly control equipment by adding remote I/O modules (cases that we find with some of our customers), even if in the majority of cases, we communicate with a BMS.

What are the advantages of using the Wattsense service in this project?

First of all, it was the diversity of the protocols offered and the responsiveness of the Wattsense solution that made us decide to integrate it into our Dreams © system, created to manage and enhance the flexibility of electricity consumption.

In addition, the possibility of fully configure the solution remotely constitutes a real advantage compared to competing solutions. Depending on the needs of our customers, it is possible to add the collection of data available in the address table of the PLC with just one click.

As we mentioned, the Wattsense solution is more affordable than the one we previously used.

The Eqinov DR'IVE © box is particularly simple to install for our customers since it integrates the Wattsense solution in a box pre-wired by Eqinov that the customer only has to power it electrically and connect to its internal network by Ethernet cable if desired.

Discover the Drive solution to remotely monitor your equipment.

Want to learn more about the Wattsense connectivity solution?

Discover our solutionContinue reading